- PRODUCT LIST

- Filling Line For Sterile / Non Sterile Application

- Automatic Inspection, Leak Testing & Inline Head Space Checking Machine

- cGMP Part Washer

- Autoclaves

- Rotary Piston Pumps & Needle

- Dispensing & Metering System For Liquid

- HEPA Filters

- OUR TEAM

- EVENTS

- CONTACT US

- ABOUT

GIGA FILTER® Series ULPA / HEPA Filter / Medium Efficiency Filter

GIGA FILTER SERIES

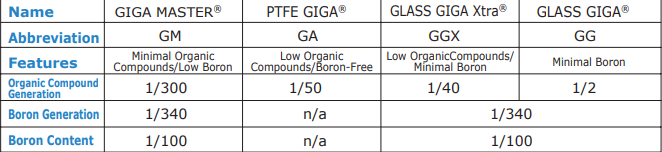

Product Lineup

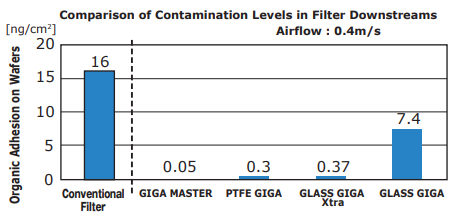

(Comparison to silica tested conventional filters)

・The world’s first ultra high-efficiency filter specifically created for the next generation of

semiconductor and liquid crystal manufacturing.

・Non-Organic particle testing: All GIGA Filters are factory Silica tested (as opposed to

testing by DOP or PAO organics); PSL (Poly Styrene Latex) testing is available by request.

Features

GIGA MASTER FILTER

・In addition to minimal Boron generation, the GIGA MASTER is the world’s first filter that can

reduce the amount of organic contaminants on wafers to 0.05ng/cm2

PTFE GIGA FILTER

・99.99999% (7N) Ultra High Efficiency; Low Pressure Drop; Boron-Free

GLASS GIGA Xtra

・Minimal Boron; Reduces amount of organic contaminants on wafers to 0.37ng/cm2

GLASS GIGA

・Media Boron content reduced to 1/100 in comparison with silica tested conventional filters;

Boron generation greatly reduced.

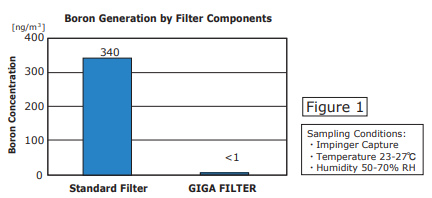

Boron Generation

GIGA Filter downstream airborne Boron concentrations have been shown to exhibit far lower

amounts compared to standard ULPA Filters. When GIGA Series Filters are employed,

cleanroom Boron concentrations may be maintained at less than 10ng/m3.

Organic Compound Adhesion

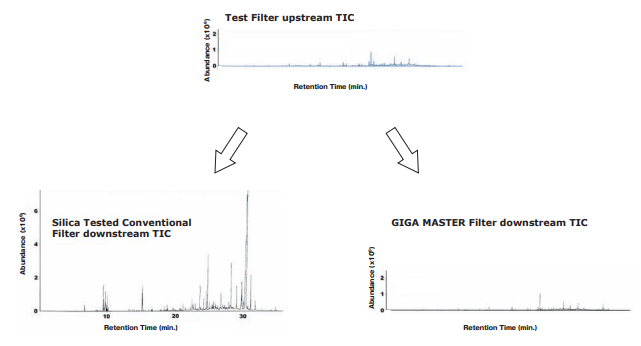

The data below shows a comparison of organic adhesion on wafers between a GIGA Master Filter and a conventional ULPA filter. Figure 2 illustrates organic adhesion on exposed wafers through Total Ion Chromatograms (TIC) of the upstreams and downstreams of the

tested filters. Whereas there is a marked increase in organic compounds between the upstream and the downstream flows of conventional silica tested filters, the GIGA MASTER Filter TICs indicate

no significant increase.

Organic Compound Wafer Contamination

It is known that adhesion of organic compounds on silicon wafer surfaces lowers the pressure resistance of gate oxide films. Figure 3 shows wafer organic adhesion after 24 hours exposure to airflows from each filter. The lowest amount, 0.05 ng/cm2 appears downstream of the GIGA MASTER Filter. Downstream concentrations were: PTFE GIGA

0.3 ng/cm2, GLASS GIGA Xtra 0.37 ng/cm2, GLASS GIGA 7.4 ng/cm2, with silica tested conventional filters exhibiting the highest concentrations at 16 ng/cm2