- PRODUCT LIST

- Filling Line For Sterile / Non Sterile Application

- Automatic Inspection, Leak Testing & Inline Head Space Checking Machine

- cGMP Part Washer

- Autoclaves

- Rotary Piston Pumps & Needle

- Dispensing & Metering System For Liquid

- HEPA Filters

- OUR TEAM

- EVENTS

- CONTACT US

- ABOUT

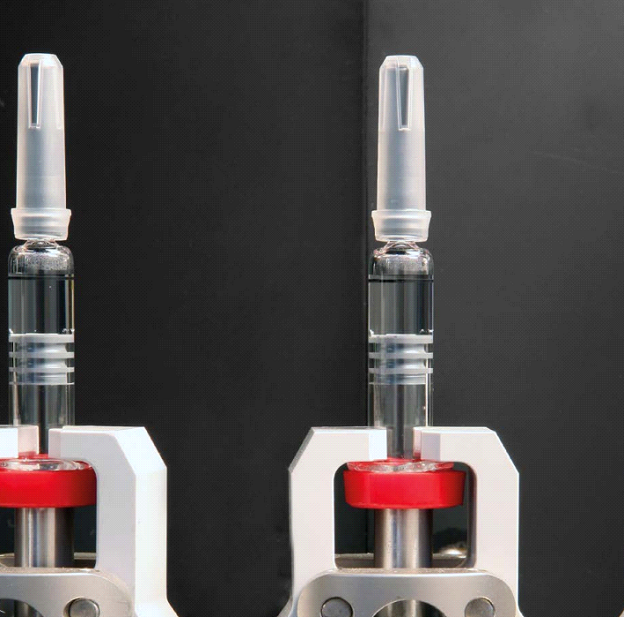

PFS

- The basic machine has been designed for the inspection of reflecting particles (glasses, fibers, etc), non-reflecting particles (black spots, hairs, etc), and fill level inspection.

The standard configuration includes:

• Loading system by means of trays or in-line connection

• Vision inspection carrousel with three particles detection stations and fill level inspection

• Dedicated exit for accepted products

• Dedicated exit for rejected products

- The basic machine has been designed for the inspection of reflecting particles (glasses, fibers, etc), non-reflecting particles (black spots, hairs, etc), and fill level inspection.

The A&V E machines, developed to process syringes , offer the ideal solution to ensure parenteral products are essentially free of foreign particles, that can affect their sterility, and other container esthetic and functional defects.

Multiple inspection stations can be integrated within the system:

• Particles floating in the liquid

• Heavy particles • Product fill level

• Container cosmetic and functional defects

• Leakage defects using High Voltage & Vacuum DecayOPTIONAL INSPECTIONS

• Syringes heavy particles inspection

• Syringes plunger integrity and rib inspection

• Syringes flange integrity and plunger presence inspection

• Syringes cap inclination and insertion inspection

• Syringes glass cosmetic defects inspection

• Syringes labeling inspection

• Label inspection

• Data matrix code inspection